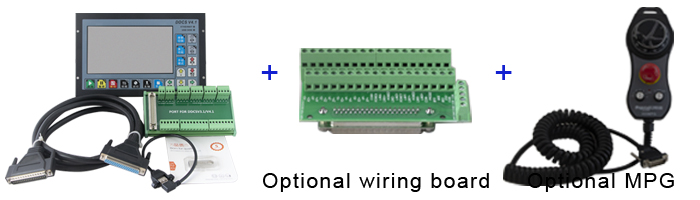

The DDCS V4.1 3~4 axes motion controller for stepper and servo system, is updated from DDCS V3.1 on software and hardware. It combines great advancement with tiny footprint of each days from past 8 years, when we released the first DDCS products DDCS V1.1 .

DDCS V4.1 the new features comparing with DDCS V3.1

1. Can transfer the files by Ethernet communication between the computer and DDCS V4.1 controller.

2. Slave X, Slave Y Or Slave Z, for Gantry machine with two independent motors on the main axes.

3. Servo Spindle can be connected to PUL/DIR output when selected;

4. We add Polar coordinate programming commands and Rotation commands, and completed Radius compensation commands on DDCS V4.1 controller.

5. DDCS V4.1 controller upgrades the motion algorithm, by Machining profile accuracy configuration, makes a long g-code program with short line segments running smoother.

6. No matter how big program file it is, system can quickly active the function of Start from Specified line and Start from closest point in few seconds.

7. Improve the simulation function. During the simulation, you can adjust the FRO and observe whether the programming path meets the expectations and check the soft limits. During the simulation, it can be paused, and when press the Start key again, the system will continue to simulate from the pause breakpoint.

8. DDCS V4.1 added driver alarm input ports, and can configurate the ports No.as you want.Same as DDCS-Expert.

9. We add cycle encoder for A axis, which is good for unlimited rotation for A axis.

10. Added the window for analysis prompt.

11. Suppport International coding, almost support all language, the users can add his language for the control system.

12. Increased the Parameters about the acceleration when Estop, to avoid collision by Stop when Estop the machine in high speed, edit the related parameters and system can give a smooth stop, this means there is no position loss.

13. System FPGE cited 32 -bit speed generator, with higher resolution for the speed / acceleration, it means higher positioning accuracy.

14. Screen size: 7 inch.